[av_textblock size=” font_color=” color=”]

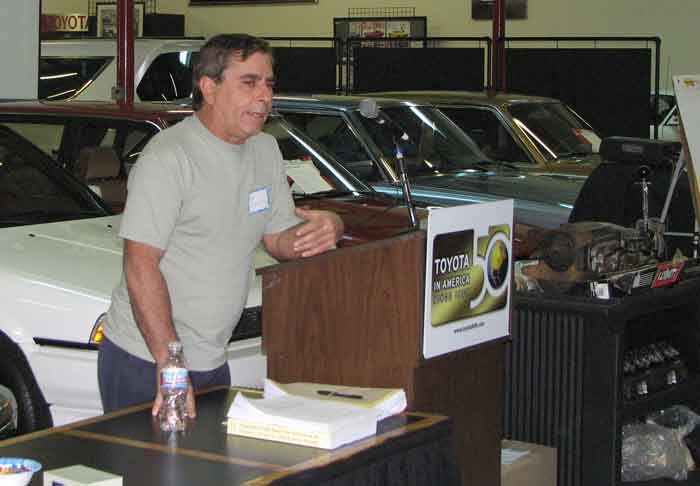

C1 Cooling Issues

Presenter: Jeff Reade, #33

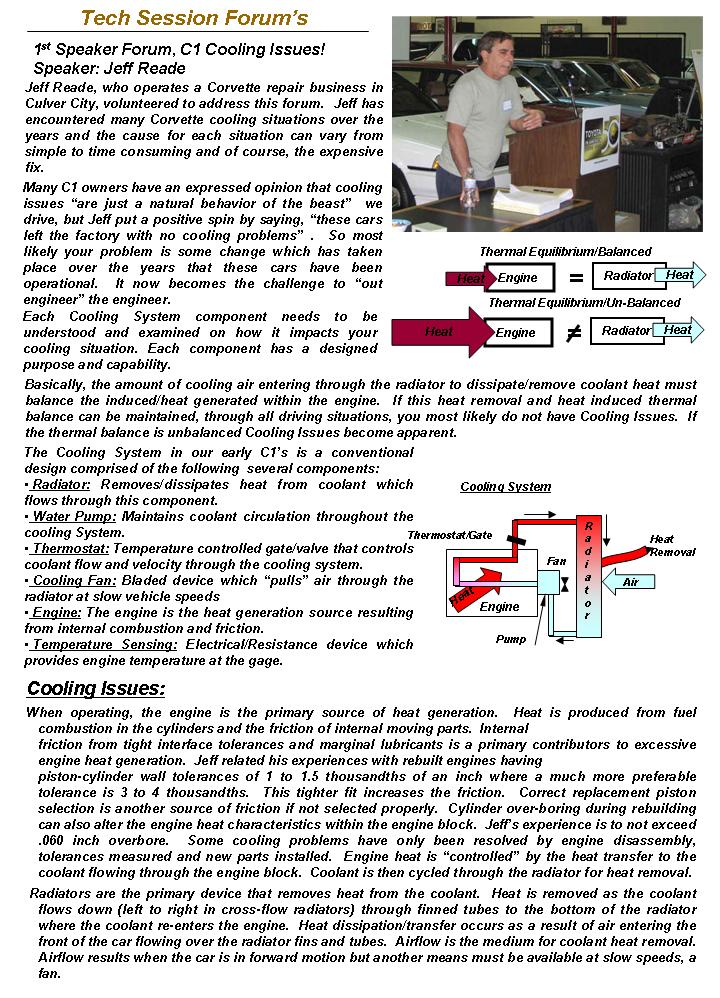

Cooling System Components

1. Radiator: This is always the initial component in question since it is the primary method of heat dissipation from all the heat generated during engine operation. For this heat dissipation to occur a constant air flow must flow through the radiator “fins” during car operation. Radiators are fabricated using material with good thermal (heat) transfer properties and in most cases copper/brass or aluminum.

2. Water Pump: This item is attached to the front of the engine and pumps the coolant medium (water, coolant/water, etc.) through the engine and radiator. The pump is rotated using the crankshaft pulley via a belt and inside the pump is a wheel with blades/fins that rotate in a cavity pumping a coolant liquid. The coolant is “sucked” from the bottom of the radiator (lower hose) and pumped into the engine and circulates through passages inside the engine block. As the coolant is circulated inside the engine the coolant gets hotter because it absorbs the heat generated from engine operation. Ultimately the coolant is pumped out of the engine and back into the top of the radiator (upper radiator hose). The coolant than falls (gravity) to the radiator bottom through the radiator coolant tubes and cools dissipating heat to the air flowing through the radiator tube-fins. Later C1’s changed the “gravity” designed radiators to a cross-flow system where the coolant flows from side to side instead of top to bottom.

3. Coolant: Initially most C1’s were delivered with water as a cooling medium which works good. However, over the years a chemical coolant has been added and the primary benefits are lowering the freezing point and raising the boiling point of the mixture. Chemical coolant mixture usually are a 50/50 coolant to water ratio which is advertised as the most efficient operational heat transfer. Most coolants do have a life expectancy and should be drained and refilled every 2 years.

4. Engine Fan: The engine fan is usually mounted on the water pump shaft. As pointed out earlier, this shaft is rotated by the crankshaft using a belt connection. The primary purpose of the fan is to draw air through the radiator when the car is standing or traveling at slow speeds. At higher speeds the forward motion of the car forces the air through the radiator.

5. Temperature Sensing: This item does not influence the cooling system function but it is the means to “know” at what temperature the engine coolant is operating. This sensor is usually located in the forward and upper part of the engine (intake manifold) and converts the temperature into some type of temperature gage reading at the dashboard.

This information was submitted recently from Chapter Member Ken Adrianse:

At our November 2007 SACC Tech Session, Jeff Reade mentioned that a 170 degree thermostat would help some C1’s that have overheating problems, but that he has not been able to find one in many years. I have been looking for a 170 degree unit for my C2 for some time (in all the wrong places) and finally did so last week on EBay. GM part number 10220957, Gr.1.246 (AC Delco #131-84) 170 degree thermostat is available at any GM dealer or AC Delco store. The AC Delco outlet that I called sells them for $8.49.My local Chevrolet dealer told me this morning that this part is still listed for 1953-62 Corvettes and retails for about $13.00. They are packaged in a standard AC Delco box and made in the USA.I thought that some of our SACC members may be interested in this information as hot weather is only a few months away.Ken Adrianse805.493.8010

Southern California Solid Axle Corvette Club

[/av_textblock] [av_button label=’Tech Topics Home’ link=’page,125′ link_target=” size=’small’ position=’center’ icon_select=’no’ icon=’ue800′ font=’entypo-fontello’ color=’theme-color’ custom_bg=’#444444′ custom_font=’#ffffff’]