|

|

|

|

Arial Shot of the parking lot prior to the beginning of the Tech Session. The location was member Mike Gibbon’s business location. Mike’s business is supplying local movie sets with weapons from almost any time period you might want.

|

|

Chapter President, Bruce Fuhrman, greets members attending the Tech Session. Bruce thanks those who assisted in the session preparation and announces upcoming Chapter events. The FI unit seen on the table was NOT a raffle item, just a prop for the first talk.

|

Chief organizer for the current and past Tech Sessions, Chip Werstein, lays out the days topics and speakers. Lunch was also available.

|

|

This topic has been anticipated for the past two tech sessions. The reason becomes quite obvious when viewing the number of FI cars in the parking lot.

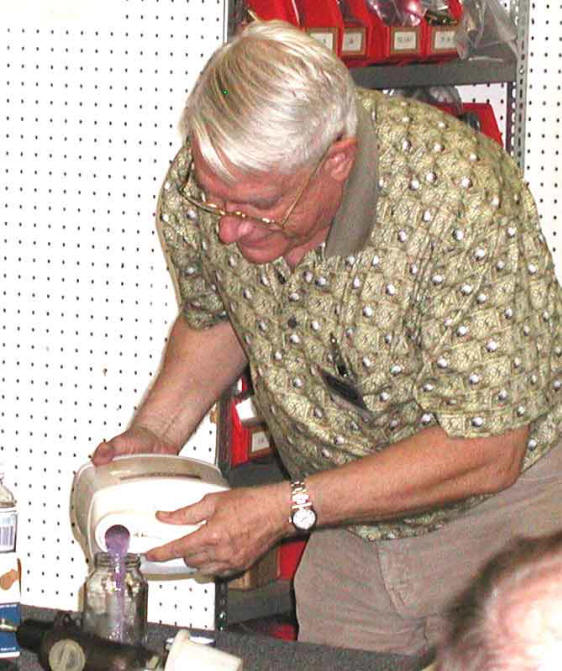

Doug Prince (shown above) began his topic with stories of how he arrived from a complete novice to be a “love-expert” on these units. Two information packed handouts were supplied by Doug during the meeting.

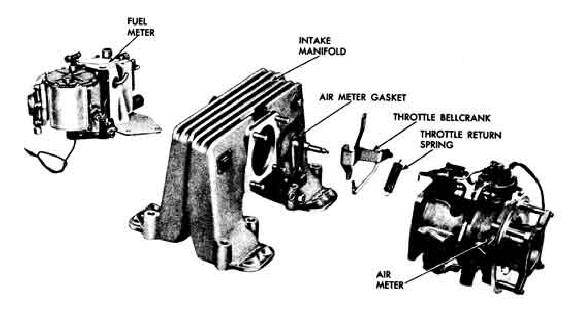

Doug described the basic components of the FI: Air Meter, Air Plenum (Dog House) and the Fuel Meter. The air is drawn through the air filter into the air meter. A venturi effect occurs near the input which controls (feeds information) to the Fuel Meter, i.e., press the throttle, draw more air resulting in more vacuum which tells the fuel meter to allow more fuel. The fuel meter is extremely sensitive to these vacuum changes and supplying fuel. This sensitivity is the reason for the instantaneous response of the FI engine. At idle, there is very little air drawn and only a small amount of fuel “injected”.

Fuel pressure is very low at idle but can increase up to 250 psi at 6000 rpm. The fuel is pushed through the .040 inch diameter “spider” lines connected to the input at the intake manifold. Small screens are located at each fuel nozzle and these have an important fuel atomization purpose. The doghouse (plenum) primarily contains air and the internal (and external) size depends on the how much air needs to go through into the engine. Bigger engines in the early 60’s had a larger squarer doghouse pushing more air.

Doug went on to explain that the primary problem (and driver complaints) stem from the use of modern day fuels. Today’s fuels are alcohol mixed with garbage components (Doug’s quote) resulting in a fuel of significantly lower vapor temperature levels. When these FI units were designed and used the leaded fuels had higher vapor temperature levels. The vapor level is the temperature which the liquid changes to a vapor. Low vapor temperatures allow these units to run rough in warmer temperatures. Another down side is shutting the engine down resulting in an engine heating hotter and trying to restart. Sometimes much cranking is required. Doug is continually seeking methods for correcting this problem, either in the FI unit or doctoring the fuel. Stay Tuned! You will hear it first here.

(editors NOTE) A modification has been built into my FI unit minimizing some of these problems, starting warm at the least. The modification introduced is to place a solenoid valve in the fuel line which when a button is pushed on the dash, allows fuel from the engine fuel pump to directly enter the spider lines and into the engine. Upon engine starting, and the button is let up, the engine does run rough for about 5 seconds until the FI unit either cools or injects more fuel into the engine. I have been driving this car for 15 years (40K miles) in all types of weather and temperature conditions.

|

|

|

So. Cal SACC member, John Hutchins, presented a talk on his 1953 to 1955 Corvette Registry. John also received the Long Distance Driven recognition for traveling from his Michigan home for our Tech Session. John does live in Mi. and is a So. Cal. Member, but he scheduled a visit to his daughters home in Lancaster to coincide with our Tech Session schedule.

John began his Registry when trying to find something to keep him busy during retirement and long winters. Now, he finds himself involved in maintaining a quantity of over 2000 cars out of the 4000+ cars produced over these years.

John passed out registration forms for those who have one of these cars and is not part of the registry. Each new car is part of the bigger puzzle. A copy of the form appears with this newsletter.

John also supplied the following statistics at the meeting.

|

|

Larry Pearson is seen above involved in demonstrating the single most problem with using the DOT 5 Silicon Brake Fluid in our old cars, no matter what automobile heritage.

Larry swears allegiance to this product based on the experience of converting many cars since the early 70’s to this product. Larry indicated that some basics facts must be followed in the process, but it should work great. Probably the most significant problem working with this product is the brake bleeding process. Silicon

brake fluid has a significant aeration characteristic which can be a problem if not recognized and taken into account while filling a brake system. Larry is demonstrating this problem by pouring the fluid quickly or shaking the bottle. This problem occurs when PUMPING THE BRAKE PEDAL RAPIDLY. The fluid initiates these microbubbles when poured into a clear container rapidly. A froth/foam sits on top and if the fluid is viewed closely, very small bubbles appear within the fluid. THESE BUBBLES WILL DISAPPEAR IF ALLOWED TO SIT FOR SOMETIME (maybe overnight). With this product characteristic in mind, the process for bleeding a brake system is to (assuming you have completely emptied and cleaned your system, discussed later) fill the master cylinder slowly and allow to sit over a period of time. Sometimes in this case “gravity bleeding” works well because you are addressing the aeration problem while permitting the fluid to flow down through the lines. IT TAKES TIME!

After a proper time, the system can be bled in a somewhat conventional manner, however, the pumping rate for bleeding is a slow (10 seconds or longer for each pump) pressure pump on the pedal. Rapid pumping introduces aeration. An attempt might be made to reclaim fluid at each wheel as silicon brake fluid is EXPENSIVE.

Other aspects of Silicon Brake Fluid.

It will last forever and not rust your system. DOT 3 and DOT 5 when mixed, will stratify, i.e. separate with DOT 3 going to the bottom. MOST times if a small amount of DOT 3 is not removed from the system and silicon is inserted, the DOT 3 can continue to corrode a system. Also, there is evidence that DOT 5 when mixed with “SOME” DOT 3 products will turn to Jello which is a catastrophe for a brake system. However, this does not always happen. The best process is to insert silicon brake fluid when overhauling a current system or installing all new hardware. Even old brake-lines can retain old DOT 3 if not flushed adequately. One process is to inject a Brake Cleaner product into the line, let sit and blow with compressed air several times. Caution: Brake Cleaners are great paint removers!

Larry Pearson is a advocate of Silicon Brake Fluid and says everyone should eventually change over but as he pointed out, certain characteristics must be considered. The myth that silicon brake fluid is more compressible is not true IF you get all the air bubbles out. Most shops and dealerships don’t use the product because of the time involved and not a complete understanding of the product. Larry says, “Try It, You Will Like It”.

Editors Note: Everything Larry reported is what I found out the hard way. I was installing all new 4-wheel disc brake system on my ’56 Chev and wasn’t aware of this delicate process. Once into the bleeding operation I could not achieve a hard pedal and after period of time I just left the car overnight and part of the next day. Upon returning the brakes had a significantly harder pedal and a more slower bleeding continued. It took about 3 days to finish the process but the results are perfect. After several years the fluid is full and CLEAR. If I had only talked to Larry sooner!

|

|

| Sometimes the transition between Speakers isn’t as smooth as one plans. In the above instance, the 4th speaking group, Chip Werstein (lt.) & Mike McCloskey (rt.) begin to edge the 3rd speaker, Larry Pearson off center stage. Larry gets so involved in getting all the information across to the audience, that time “fly’s”. |

|

They did a “Tag Team” presentation of unique tools that can be an asset in working on Solid Axle Corvettes. Some were store bought and some were “made locally” by the presenters. Tools ranged from axle pullers to trim installation. The most unique was Chips special tool to straighten cove trim. Patent not yet applied for! The gear ratchet gear wrenches were considered the best thing since sliced bread and are readily available at most auto parts stores. There was a lot of nodding of heads in the audience when a particular challenge was mentioned and then the appropriate solution

|

|

| Southern California Solid Axle Corvette Club |

|

|