[av_textblock size=” font_color=” color=”]

[/av_textblock]

[av_button label=’Tech Topics Home’ link=’page,125′ link_target=” size=’small’ position=’center’ icon_select=’no’ icon=’ue800′ font=’entypo-fontello’ color=’theme-color’ custom_bg=’#444444′ custom_font=’#ffffff’]

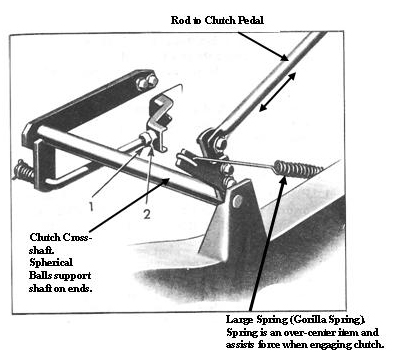

| C1 Clutch Linkage

Lubrication Doug Prince, #47 |

||||||||

|

||||||||

|

Southern California Solid Axle Corvette Club |

||||||||